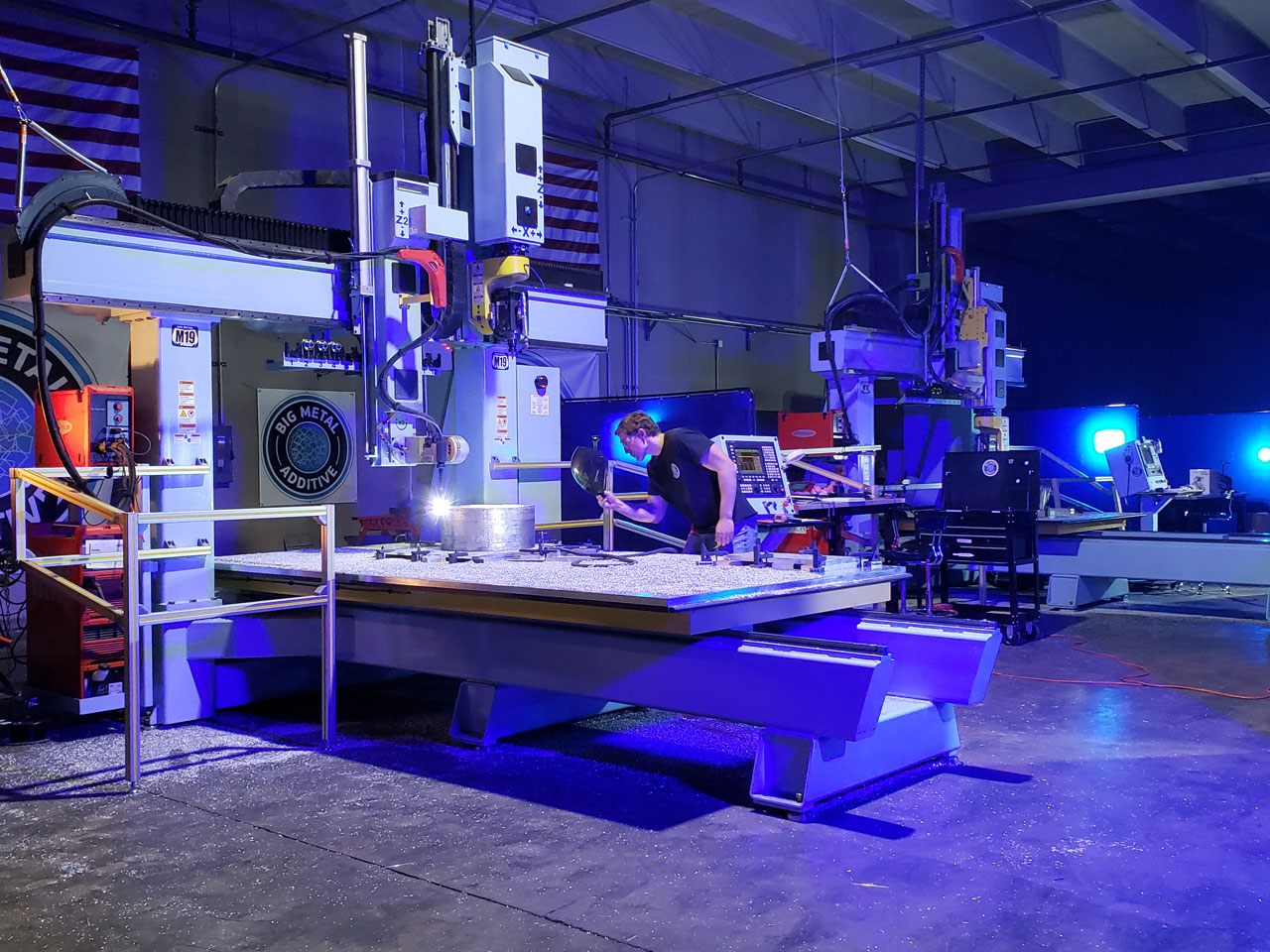

Solving customer problems with the largest and most sophisticated metal hybrid additive manufacturing capability in the industry.

Offering an unprecedented opportunity in producing large metal parts quickly for customers seeking a wide variety of solutions, from innovative design exploration to replacement of obsolete parts.